Utilisation des isotopes stables de Cd, Zn, Cu, Ni et Pb pour quantifier le compartiment échangeable des éléments trace métalliques

Field settings

The Riou Mort and Riou Viou rivers drain the Decazeville basin (Aveyron, SW France) and are affected by heavy metal pollution when running through a former (1842 – 1987) industrial Znore smelting plant (Fig. 1). During the 145 years Zn-ore smelting continued, industrial processes were continuously improved allowing increasing amounts of Zn-ores to be processed and increased extraction yields. Until 1922, zinc was first produced from ZnCO3 by thermic reduction with coal. Subsequently, ZnS was oxidised and solubilised with sulphuric acid before Zn was extracted by electrolysis. The resulting residues were then re-processed by coal-fired thermic processing, which was replaced by a second electrolysis-based process in the late 1970s. After accidental seepage in 1986, Zn production stopped. From 1987 to 1990, remediation work was undertaken. Part of the waste was deposited in storage basins with underlying and overlying mud (Audry et al., 2004). Soils surrounding the river were contaminated by contaminated water from the Riou Mort during flood periods and through atmospheric deposits from industrial emissions. Soil location and sampling One fluviosol (noted V1) was sampled at a floodable site near the Riou-Mort, downstream from the Viviez industrial complex (Fig. 1). Given its location, it may have been polluted by atmospheric deposition, sediment deposition, or by polluted water from the Riou Mort during floods. The topsoil was sampled on a 1m2 plot cleared of vegetation. The first 20 centimetres were homogenised and quartered. This soil sample was air-dried and sieved at 2 mm before analysis. Airdried samples were stored in plastic bags until use.

Granulometric fractionation

The constituents of the solid phase were sieved in water and then centrifuged to separate them into four granulometric fractions (Ducaroir and Lamy, 1995): coarse sand (2000-200 µm), fine sand (200-50 µm), coarse slime (50-20 µm) and fine slime + clay (< 20 µm) defined as “fine fraction”. Soil suspensions (250 mL of ultra pure water + 100 g of dried 2 mm-sieved soil) were first dispersed mechanically with an end-over-end shaker for 16 h before sieving. The first three fractions were then separated with 200 µm, 50 µm and 20 µm sieves using ultra pure water. The last fraction (< 20 µm) was obtained by centrifugation at 7500 rpm for 12 minutes.

Physical analyses

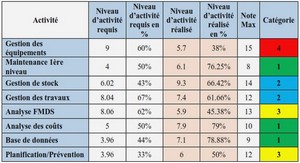

Physical methods were used only on mineral phases present in the soil. The organic matter was first separated. X-ray diffractometry (XRD) was performed on bulk powders and oriented preparations with an INEL CPS 120 diffractometer using Co Kα radiation. The oriented preparations were analysed in the air-dried (AD) and ethylene glycol-saturated (EG) states. Mineral phases were identified using optical metallographic microscopy and then Scanning Electronic Microscopy (JEOL6360LV) coupled with Energy Dispersive Spectrometry (PGT Sahara) on soil grains mounted in polished sections. Chemical analyses were carried out with a CAMECA SX 50 (Samx automation) Electron Probe Micro Analyzer equipped with three spectrometers (LiF, PET and TAP crystals) at the “Service Microsonde Electronique” of Toulouse University (France). Analytical conditions for oxide minerals were 15 kV for the accelerating voltage, 10 or 20 nA for the beam current depending on minerals, to avoid damage under the beam, 10 s counting time on peak and 5 s for background. Peaks and background (Bg) positions were carefully selected to minimize interference especially on the Cd peak. For Cd analysis in coke grains, the detection limit was improved by increasing the counting times (60 s peak, 10 s Bg). For sulphide minerals and pure metals, higher voltage (25kV) and a higher current (20 nA) were used. Standards were pure metals for As and Sb, synthetic or natural minerals for Mg (periclase), Ca and Si (wollastonite), Mn and Ti (pyrophanite), Al (corundum), Fe (hematite), Ba (barytine), Na (albite), K (sanidine), Cr (chromite), Sn (cassiterite), P (graftonite), Ni (nickel oxide), Sr (Sr-Ti oxide), Pb (synthetic glass), Zn (sphalerite), Cu and S (chalcopyrite), Cd (greenockite). Depending on the mineral matrix, detection limits ranged from 0.41 wt% for Pb to 0.07wt% for Al in standard conditions. The Cd detection limit ranged between 0.18wt% for Fe oxide minerals and 0.10wt% for coke. In optimized conditions they were lowered to 0.05wt % and 0.03wt %, respectively. In order to reach lower detection limits for Cd, laser ablation inductively coupled plasma mass spectrometry (LA-ICP-MS) analyses were performed, at Toulouse University (France). LAICP-MS studies were conducted with a commercial femtosecond Ti:Sa laser system (Amplitude Technologies Pulsar 10) based on the Chirped-pulse amplification (CPA) technique. In this set-up, pulses are amplified to 12 mJ by a regenerative and a multipass amplifier. This system provides laser pulses at 800 nm with variable pulse energy and a pulse duration as short as 50 fs. The linearly polarized laser beam is injected in a BX51 microscope (Olympus). The beam is reflected by a 45° dielectric mirror and focused down to the sample placed in an ablation cell mounted on a XY stage, using a 10 cm focal length silica lens. These conditions imply a beam diameter of 100-120 µm. Optimization and external calibration was performed with the NIST 612 glass standard and recovery was checked on a second glass standard, NIST 610. Both glass standards are good proxies for slag analysis, and they are also used for coal and coke analyses in absence of other suitable standards. This is a limiting parameter for the accuracy of measurements on such samples. Each analysis was normalised to the Al values determined by the electron microprobe. This enabled insitu analysis of selected grains in polished sections. Due to the beam size, only the biggest coal and coke grains were suitable for laser ablation. One spot per grain was analyzed, but several grains of similar type were analysed when available. The theoretical minimum detection limit at the 99% Partie II-Chapitre II.2 – 59 – confidence level was determined by Poisson counting statistics, 2.3* √ (2B) where B is the total count in the background interval. The total count ranged between 0.5 and 3.3 mg.kg-1 for Cd depending on the analysis. One percent uncertainty was assumed on the elemental concentrations of the reference material and 3% uncertainty on the values of the internal standard was propagated throughout the calculations. The calculated relative precision for the laser analyses ranged from 14 to 32 % for Cd. Chemical extractions The metal distribution was quantitatively estimated by sequential extraction. The procedure used in this study, summarized in Table 1, was initially proposed by Tessier and Campbell (1991). All reagents used were of analytical grade. The six extraction steps allowed the following geochemical pools to be distinguished: water-soluble (STEP 1), exchangeable (STEP 2), acidosoluble (STEP 3), reducible (STEP 4a, 4b and 4c), oxidable (STEP 5 a and b) and residual (STEP 6). The two first pools removed all the elements present in soluble form (i.e. salts, STEP 1) and, the exchangeable cations, i.e. elements sorbed on minerals such as clays and organic matter (outer sphere complexes or weak bonds such as Van Der Waals bonding (Yong et al., 1993, STEP 2). In STEP 3, the elements linked to particle surfaces by pH-dependent bonding were mobilized (Benitez and Dubois, 1999; Cornu and Clozel, 2000; Gleyzes et al., 2002). The ‘‘reducible’’ pool (4a, 4b and 4c, STEP 4) dissolved Fe–Mn oxy-hydroxides. In step 4a the use of a hydroxylamine-hydrochloric acid mixture selectively dissolved Mn oxides in 30 min while minimising iron extraction (<5%) (Chao, 1972; Pickering, 1986). The oxidable pool was then extracted by the sequence H2O2 (STEP 5a) and HNO3 (STEP 5b). Organic matter was oxidized in STEP 5a. Partial oxidation/dissolution of sulphide ore pieces may also occur at this step (Marin et al., 1997; Filgueiras et al., 2002): HNO3 was used to ensure the total solubilization of sulphide inorganic forms (5b). The remaining soil constituents, i.e. silicate of natural origin (to which some phases of metallurgic origin might be added in this soil) were entirely digested in the sixth and last step (STEP 6). We chose to artificially distribute a standard error of 5% on each geochemical pool in the results.

Chemical Analyses

Bulk soil and the different granulometric fractions were analysed: pH, organic C content, total N and Cationic Exchange Capacity (CEC) (Table 2 and Table 3). The bulk soil and the granulometric fractions were digested successively using suprapure H2O2, bi-distilled HNO3 and suprapure HF. Concentrations of trace elements were determined using a Perkin-Elmer SCIEX quadrupolar ICP-MS Elan 6000 at the Laboratoire des Mécanismes et Transferts en Géologie (LMTG), with a detection limit of between 0.5 and 5 µg.L-1 depending on the element and an external precision of ± 5%. An internal standard containing In and Re was used to correct instrumental drift and a multi-elementary external standard was used for quantification. The recovery of metal concentrations obtained with the SRM 2711 contaminated soil standard (NIST) to Partie II-Chapitre II.2 – 60 – certified values was better than 95%. However, an external error due to experimental incertitude of 5% was taken into account for sequential extraction results, in addition to the analytical error.

Isotopic Exchange Kinetics

Cadmium and Zinc Spiking Solutions. Enriched 106Cd and 67Zn (94.6% and 79.013% atom abundances for Cd and Zn, respectively) were obtained from Spectrascan® concentrated stock solutions (≈10 mg.L-1, HNO3 2.5% Sub-distilled ultra high purity). Stock solutions were first calibrated by isotopic dilution with International Standards (Inorganic Venture®) to determine their exact concentrations. From these solutions, two working solutions were prepared by concentrating the stock solutions (evaporation ≤60°C; spot dissolution in HNO3 0.46N), to obtain 10 g.L-1 of Cd for the first solution and 100 g.L-1 of Zn for the second. Protocol. Soil suspensions (1 g of soil + 10 ml ultrapure water) were shaken for 16 h at 20- 23°C on a roller (40 cycles per minutes) to obtain stationary Cd and Zn concentration in solution. At t = 0, 10 µl of spike solution was injected in the prepared flasks of soil suspension, so that the amount of 106Cd and 67Zn added to each sample corresponded to 0.2% and 0.07% of total Cd and Zn, respectively. The kinetic aspect was addressed by measuring the evolution of exchange at eight time steps: from 1 min to 1 or 2 weeks (for Cd and Zn, respectivel, Table 6). For each time step, 2 ml of the spiked soil suspension was collected and filtered through 0.2 µm syringe filters (Minisart® Sartorius). Each sampling point was triplicated (three samples filtrated in parallel) to check the reproducibility of the method. Three filtration blanks were performed to check the contribution of the filter. All the filtered solutions were weight-diluted in ultra pure HNO3 2% and stored at 6°C until analysis. E-value determination. The isotopic exchangeable Cd and Zn (ECd and EZn values) calculated here correspond to the “Ea” value defined by Hamon et al. (2002), i.e. the total isotopically exchangeable pool. This pool (Ea) is the sum of isotopically exchangeable elements in both solid (Ee) and solution phases (Cs). ECd and EZn values were determined in each filtrate by isotopic ratio analysis using a suitable isotopic dilution formula (Eq. 1, adapted from RodriguezGonzalez et al, 2005): ( ) ( ) ( ) ( ) F STD F STD S S STD S IN IT IN IT IN IT * A A * M M E Q * − − = IN S IT [1] where: – QS is the amount of added spike (in µg) for 1 g of sample; – MSTD and MS are the atomic masses of the element concerned in the standard and in the spike solutions (in g/mol), respectively; – ASTD and AS are the 114Cd (64Zn) abundances in the standard and spike solutions (in %), respectively; – (IT/IN)S, (IT/IN)F and (IT/IN)STD are isotopic ratios 106Cd/114Cd (67Zn/64Zn, resp.) measured in the spike, the filtrate and the standard solutions, respectively. Partie II-Chapitre II.2 – 61 – ECd and EZn values were calculated for each triplicate. The average value and corresponding standard errors were then determined for each time step.

Isotopic Ratios Analysis

The isotopic ratios Zn Zn 64 67 and Cd Cd 114 106 were analyzed in the filtrate, the spike, and the standard solutions using quadrupolar Inductively Coupled Plasma Mass Spectrometry (ICP-MS, Agilent 7500c, Agilent Technologies, LMTG). The isotopes 63Ni, 105Pd and 118Sn were also analyzed to correct any isobaric interferences on 64Zn, 106Cd and 114Cd. Isotopic ratios were analyzed on 25 blocks of 100 replicates for each sample to obtain precise analytical measurements (SE ≤2.5%). The analytical precision on the external multi-element isotopic standard measurement was less than 0.5% compared to certified values. The need for correction for mass bias was avoided by the simultaneous analysis of the isotopic ratios of filtrate, spike and standard solutions integrated in the E-value calculation formula (Eq. 1). The stability of the isotopic composition during the analysis was checked on a sample group (Freydier et al., 1995) and found to be negligible compared to the instability induced by the spiking method.

Introduction Générale |