THOR abdomen prototype finite element model development and validation

A finite element model of the THOR dummy has been developed by NHTSA. The validation of this model under impact conditions needs to be confirmed, especially for the abdomen region with regards to loading velocity dependency. The validation regarding test data should be assessed for both impactor and seatbelt loading cases. In order to be able to reproduce a variety of test configurations, the prototype abdomen described in Compigne et al. 2015 should also be available as a finite element model, including the APTS sensors, and validated against test data. Recently performed tests from NHTSA’s VRTC 1 on this prototype abdomen provide data for validation. Once the validation versus test data will be assessed, the prototype abdomen model could be used to propose design changes or material modifications in order to improve its biofidelity.

Finite element model of the THOR abdomen

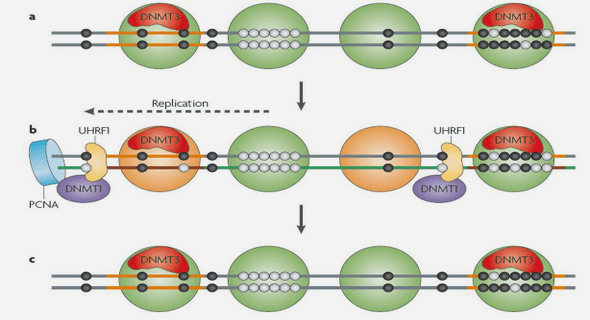

A finite element model of the THOR dummy under LS-DYNA has been developed since 2000 by NHTSA and other partners. The version 2.0.5 model of the Mod-kit dummy was used. The model is described in THOR FE 2 Manual (Panzer et al. 2015). The model has been built using CAD 3 drawings of the dummy. It contains 469 parts, approximately 460 000 elements and 237 000 nodes. Rigid and deformable material properties derived from impact test data are used. Figure 2.1a shows a global view of the dummy model. Figure 2.1b shows the upper and lower abdomen of the dummy model. Both abdomens consist in a front and a rear foam block, linked to a plate attached to the dummy spine. Tables 2.1 shows the properties of the main deformable parts of the dummy abdomen and pelvis. According to GESAC, Inc. 1999, the front foam material is an open cell charcoal polyester and the rear foam material is a closed cell sponge rubber. Figure 2.2 shows the material curves associated with the upper and lower abdomen parts for different strain rates. These curves are used for hyperelastic material models that allow strain rate dependency (mat_057: low_density_foam and mat_083: fu_chang_foam, detailed in Appendix C).

Evaluation

The component-level response of the dummy has been evaluated in THOR FE Manual (Panzer et al. 2015) according the the procedures detailed in THOR Certification Manual (NHTSA / GESAC, Inc. 2005a) and sled tests performed at 11 m s−1with a 16 g’s deceleration peak (protocol from Untaroiu et al. 2009). For the global evaluation, the belt forces, landmarks trajectories and kinematics, neck load cells signals and femur forces were in fair adequation with the test data. However, regarding the component level evaluation, the upper and lower abdomen responses showed margin for improvement. Figure 2.3a shows the upper abdomen validation under a 8 m s−1 impact with a 18 kg wheel shaped impactor according to Nusholtz and Kaiker 1994 and Figure 2.3b shows the lower abdomen validation under a 6.1 m s−1 impact with a 32 kg impactor according to Cavanaugh et al. 1986. The response of the FE model shows a higher force response than the test data for both abdomen regions. This is believed to be due to imprecisions in the material characterisation for the abdomen foams and the pelvis.

Improvements

Improvements to the material properties of the THOR dummy model were performed as part of this work The stress values of the pelvis material curves were multiplied by 0.16 according to tests performed by Toyota Motor Corporation and the front foam material properties have been re-characterised as part of this work to introduce material strain rate effect, the front foam being the part that influences the most the lower abdomen response. Drop tests were performed on cubic foam samples by by Toyota Motor Europe at strain rates from 6 × 10−4 s −1 to 120 s−1 . The original material model was a simplified hyperelastic foam model (mat_057: low_density_foam) and was replaced by a rate dependent hyperelastic foam model (mat_083: fu_chang_foam) with new tabulated curves for different strain rates as seen on Figure 2.4.The modified dummy model has been validated using tests performed by NHTSA’s VRTC and provided for this project. Two conditions were performed: a seatbelt loading reproducing the PMHS tests from Hardy et al. 2001 and an impactor loading reproducing the PMHS tests from Cavanaugh et al. 1986. For the seatbelt condition, the belt was pulled at the back of the dummy by a pneumatic system, the dummy back being free. Figure2.5 shows the two different set-ups. Three different pressures were applied to the belt retraction system: 4.5 bar, 5.5 bar and 6.6 bar. The 6.6 bar condition corresponds to the loading applied to PMHS in Hardy et al. 2001. Figure 2.6a shows the different belt retraction profiles. For the impactor case, a 32 kg mass (diameter 25 mm) stroke the dummy with an initial velocity of 6.1 m s−1 . In the simulations, the dummy was positioned seated according to the physical test and gravity was applied for 500 ms in order to obtain the initial geometry for the simulations. Initial stresses and strains resulting from the gravity deformation were not taken into account. Figure 2.7 shows the positioning and gravity deformation process. A fixed timestep of 4 × 10−4 ms was achieved through mass scaling.

Seatbelt condition

The seatbelt conditions having a similar input profile, the dummy model response will be considered under the 6.6 bar condition since the standard dummy abdomen has only been tested under this condition. The results are presented on Figure 2.8. The belt retraction over time from test data was applied to the model, the back of the dummy being unrestrained. This condition corresponds to a 6.6 bar pressure applied to the belt retraction system. The model predicts well the response from test data, although there is a second force peak from the test data, that is not entirely reproduced by the simulation. But the second peak in the simulation is due to the seatbelt almost sliding over the pelvis, which is not the same phenomenon as in the test. Figure 2.9 shows the deformed shape of the model for different simulation times.

Impactor condition

The dummy model response under impactor condition can be seen on Figure 2.10. The test data were not available over time, only as force / penetration graph. The force from the simulation was filtered at CFC 4 180, the same way as the test data, which reduced the observed force peak. However the simulation results show a too high force and less penetration compared to the test data. The higher peak force is due to the abdomen foams being fully compressed and the impactor contacting the abdomen plate as it can been seen on Figure 2.10c. Here the test on the physical dummy is not properly reproduced by yhe model in terms of dummy behaviour. Figure 2.11 shows the model deformed shape along the simulation.