Organisation cristalline et renforcement Exemple du polyamide-12

Les mécanismes de renforcement sont intimement liés au confinement de la matrice

De nombreuses études expérimentales décrites dans le chapitre 1 suggèrent que la ductilité est obtenue lorsque l’épaisseur moyenne des ligaments de matrice est inférieure à une valeur critique, Lc, caractéristique de la matrice et indépendante de la taille et de la nature des particules. L’origine physique d’une telle distance critique n’est pas clairement déterminée. En particulier, nous avons vu que les modèles proposés ne parviennent pas à décrire certains faits expérimentaux tels que la dépendance en température de Lc ou les effets de la mise en forme.

Dans ce chapitre, nous nous intéressons plus particulièrement au rôle de l’organisation cristalline de la matrice en étudiant les systèmes de polyamide-12 renforcé décrits dans les chapitres précédents. Des observations en MET révèlent l’agencement local des lamelles cristallines et montrent que l’organisation cristalline ne forme pas de couches orientées mais semble déterminée par les écoulements locaux lors de l’injection. En appliquant un traitement thermique à ces systèmes, nous montrons également que des différences d’organisation cristalline de la matrice ont des effets dramatiques sur le renforcement.

Processing and thermal treatment Impact test bars were injected according to ASTM/ISO requirements. A thermal treatment was applied to some of the injected samples as follows. Test bars were first melted at 200°C for 20 min in a mould and under a press to avoid contact with air. Melted bars were then slowly cooled under the press down to room temperature (1°C/min). All the bars were dried in a vacuum oven at 50°C for 24 hours prior to this treatment and kept in a desiccator until they were tested. Notches were cut according to the specifications of ISO179, after the treatment and just before impact testing.

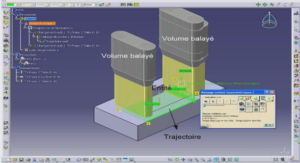

Characterization Optical micrographs were obtained under crossed polarizers from thin (~ 5 µm) microtomed sections on a LEITZ DMRXE microscope. Particle dispersions and matrix crystalline organizations were characterized by transmission electron microscopy (TEM) using stained ultrathin sections. Ultrathin sections were cut by ultramicrotomy with a diamond knife at –100°C. Osmium tetroxide (OsO4) vapor was used to selectively stain SBM particles in PA12/SBM systems. An aqueous solution of phosphotungstic acid (H3PO4, 12WO3) and benzyl alcohol was used to stain the polyamide matrix and reveal the crystalline lamellae110.

Benzyl alcohol acts as a dyeing assistant and helps diffusion of WO3 which preferentially stains the amorphous polyamide layers. Experiments were carried out with a JEOL 100CX electron microscope at an acceleration voltage of 80 kV. For each blend, particle size distribution was obtained by image analysis with the ImageJ software111 on 200 to 800 particles and over several tens of µm2 . The diameter, d, of each particle was estimated by: π = A d 2 (6.1)

where A is the area of the particle measured on the ultrathin section. Raw measurements obtained from TEM micrographs were corrected to obtained better estimations of the real distributions in the bulk. These corrections particularly concerned the cross-section effect which tends to overestimate the number of small particles and the projection effect due to the non-zero thickness of ultrathin sections. Details of this image analysis are given in a separate study.