The construction industry is a basic and important sector for the world-wide economy; however, it is known as a complicated and often underperforming segment. The industry is regarded as high fragmentation, low productivity, cost and time consumption, and conflicts. Many construction projects are recorded with overdue schedules, overrun budgets, and poor quality, which pave the way for problems to plague in the industry (Aloini et al., 2012). In construction networks, clients, consultants, contractors, designers, subcontractors, and suppliers are key nodes that are connected by interfaces embracing knowledge transfer, information exchange, financial, and contractual relationships. Yet, these networks are noted with inefficient collaborations; for instance, the splitting up design and construction, absence of integration and coordination between different functional disciplines, as well as poor communication (Behera et al., 2015).

The concept of Supply Chain Management (SCM) has been increasingly applied to many industrial sectors to improve business performance such as faster response to the variety of customer demands, lower cost, and better quality. In construction, the application of SCM concepts is frequently used to guide project managers in strategic planning to achieve partnerships with suppliers, and obtain more efficiency in operational construction (Azambuja and O’Brien 2009). However, the importance of SCM in improving construction management has been recognized since the 1990s. Papers in this specific period mostly discussed the controversial issue that whether SCM should be applied or not for construction industry due to its different characteristics from the manufacturing sector. Until the 2000s, research studies focused on the analysis and the exploration of the relevant aspects of SCM in construction, especially after Vrijhoef and Koskela (2000) introduced four roles of supply chain management in construction that motivated many scholars in studying the field.

The last decades have witnessed changes in the awareness of applying SCM in construction management. At the beginning of the 2000s, researchers in CSCM focused on the examination of some aspects such as proposing perspectives on construction supply chain integration (Dainty et al. 2001). They also explore skills, knowledge, attitudinal requirements for construction supply chain partnerships (Briscoe et al. 2001); and how to adopt SCM in the construction industry (Saad et al. 2002). From the middle of the 2000s, many authors were interested in developing in depth frameworks for solving and applying managerial problems of CSCs. For instance, an agent-based framework for supply chain coordination in construction (Xue et al. 2005), a conceptual framework for mature CSC (Vaidyanathan and Howell 2007), and dynamic reputation incentive model in CSC (Chen and Ma 2008) are only a few examples of application attempts. In recent years, researchers have paid attention to many methods and tools that are integrated to CSC to achieve the efficiency in performance: Lean concept is adopted to improve CSC collaboration (Eriksson 2010); Logistics modeling using simulation (Vidalakis et al. 2011); Logistics optimization using meta-heuristics algorithms (Said and ElRayes 2014; Kumar and Cheng 2015). Recently, CSC integrated with Building Information Modeling (BIM) is another proof that the adoption of logistics and SCM in the construction sector continues to evolve with the technological progress (Papadonikolaki et al. 2015).

Material evaluation

The collected sample of documents is reviewed following the five classification criteria mentioned in the above section. To guarantee the quality, the validity, and the reliability of the review, a crosschecking process is conducted for the document classification. In this process, two authors are required to read carefully the category criteria as well as the content of collected papers. Then, the sample is classified independently by the two authors based on their understanding of the documents. After finishing the classification, the two authors discuss together to get the agreement. For papers with different classification results between the two authors, the content analysis of the documents must be reviewed again by them until a consensus is achieved. Later, the classification list of the sample is presented to the third author who has academic and practical experiences in the field of logistics and CSCM. The third author is responsible for a quick reading of all the documents to check the validation of the classification. The third author gives the corrections for cases that are thought to be unsuitably classified. The discussion among all authors is conducted for these cases to make sure that the classification is unbiased. The cross-checking process is performed until a final agreement is achieved. This process plays an essential role in improving the quality of academic judgment for content analysis within the systematic literature review process.

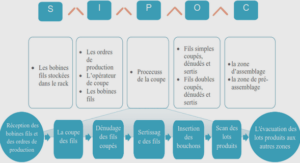

Decision levels and construction supply chain phases

For the sample, only twenty two (22) papers discuss the involvement of decision-making in the planning and design stage of CSC. Fifty (50) papers focus on decisions related to the procurement stage. There are sixty-one (61) papers that cover the decision process within the construction and delivery stage. In the stage of planning and design, strategic decisions such as CSC configuration and developing of the detailed drawings of engineering and architecture are conducted. Because of the project-based oriented perspective and the short-time relationships in construction, important strategic SCM decisions are not released in the planning and design stage. One of the most important decisions is building a strategic relationship that is usually deployed in the procurement stage. The other important strategic decision, for example, building the construction information system is often set up for the construction and delivery stage.

INTRODUCTION |