MODELISATION DU PROCEDE DE SOUDAGE PAR POINT

General Methodology for Weld Simulation

A generalized principle and methodology of weld simulation is proposed by Ferrase et al.,[FER98-1], to study the thermal characteristics in mash seam process modeling. Different stages to establish a model can be hilighted in Fig. 3.1. A basic knowledge on the process characteristics, especially on the practical parameters and the initial hypotheses is necessary at the beginning. Second, the model construction with a consideration of a complete/sectioned structure associated with boundary conditions. If it is possible, a planar- or an axissymmetrical structured mesh model is preferred to the extended complete structure in order to minimize time/cost of the computation. The optimization of the number of elements and element types could be an advantage for a frequent used model. A solid background experience of user is required on how thermal/mechanical loads and boundary conditions can be imposed to those axis-symmetric structures. In the third step, a selection of the commercial code adapted to the application is needed for simulate the problem. This step concerns mainly the existence of analysis modules in the code and the user interface facility. Fig. 3.1: Generalized methodology for mathematical modeling of resistance welding-[FER98-1]. In this study, SysweldTM code is chosen for the simulation purpose due to its features concerning weld simulation. Prior to the exploitation of a model, the validated results are essential for the application assurance. For RSW process, the validation scopes can go beyond the weld size and geometry validation. Other quantitative validation aspects, such as the thermal history validation, signal of electrode displacement, or voltage drop across the electrodes can be also conducted-[SRI03-2]. The validation process leads to the verification of initial hypotheses and the adaptation of the input parameters. The final stage is to correct/accept the model and/or hypotheses, (§Fig. 3.1).

Physical Coupling and Governing Equations

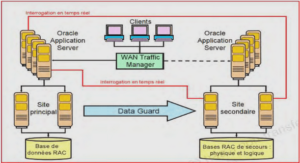

Physical phenomena involved in welding are complex. The physical interaction phenomena are the fluid flow in the molten pool of the weld, heat transfer, phase transformations induced by thermal history, stresses and strains in the weld. For the RSW, the general physics, schematized in Fig. 3.2, demonstrates the brief relationship among different aspects such as heat transfer, mechanics, metallurgy, and electro-magnetokinetics. ^Chapitre 3 – Modélisation du Procédé de Soudage par Point] 87 Fig. 3.2: Relationship among different aspects concerning the RSW process simulation-[DUP04]. Basically for the weld simulation, thermal history can be considered as a linking input for the other phenomena and that of the material properties in order to take into account for temperature dependence, (§Fig.3.2). According to the documentation [VOG92, THI92, LE MUR02], the temperature has an influence not only on characteristics of thermal contact, but also on that of electrical contact. For the coupling computational procedure, several different levels of coupling procedure can be highlighted, regarding time-step for the assembly updating : Geometry updating each macro time-step (§Fig. 3.3a); the macro time steps are defined equivalently in both electro-thermal and thermo-mechanical analyses. However, micro-time step scale for both modules may be different. In our study, the macro time step coupling programmed by user are defined for each 1/10 of welding cycle or 0,02 seconds. The coupling closed loop procedure is to perform a sequenced coupled computation or the case of modified boundary conditions, e.g. the influence of time-length of electrode maintaining stage on the thermal history experiencing in the weld. Geometry updating for each micro-time step as depicted in Fig. 3.3b; the time-step have to be equal in both macro and micro scale for both electro-thermal and thermo-mechanical analyses. Fully coupling for each micro time-step between two analyses as shown in Fig. 3.3c; In this case convergence must be reached simultaneously for both analyses at each micro time step. ^Chapitre 3 – Modélisation du Procédé de Soudage par Point] 88 Fig. 3.3: Illustration of the coupling procedure used in the spot welding simulation-[DUP04].

Governing Equations : Electrical Phenomena Formulation

According to the electrical formulation, the electrical phenomenon in RSW is individual treated to the steady state electro-kinetic problem. Ohm’s law in vector form, which is described a steady flow for the current flux can be stated as follows : J = −σ.E r ,where E = −gradV r [3.1] where ‘ J r ’ and ‘ E r ’ are current flux flowing across a section area (Amp/m2 ) and electrical field density (V/m), respectively. ‘σ ’ is the electric conductivity of the conductor (1/(Ohm.m)). ‘V ’ is scalar electrical potential (V). To calculate current, ‘ I r ’ , as the result of current density flux, ‘ J r ’, at any point of a cross section, ‘ s ’ : ∫∫ = s I J.ds r r [3.2] These conditions are associated with the conservation of the current flux, ‘ J r ’, flowing along a conductor : divJ = 0 r or according to (3.1); div(σ gradV) = 0 [3.3] Coupled Electro-Thermal Formulation : RSW is a non-linear and unsteady state problem with full coupling between electrical and thermal modules. The generalized formulation of governing equation with the internal heat generation can be established as follows : − ( . ) − .( . ) − = 0 ∂ ∂ div gradT gradV gradV Q t H ρ λ σ [3.4] In this expression, ‘ ρ(T) ’ is the mass density, ‘ H(T) ’ is the enthalpy, ‘ λ(T) ’ is thermal conductivity, and ‘σ (T) ’ is the electrical conductivity. Temperature-dependent characteristics of sheet and that of electrode can be included in the model. The full coupling between the electrical and thermal phenomena can be governed by term ‘ gradV .(σ .gradV ) ’ in the heat equation, which includes the Joule effect as a heat source. For RSW process, there are also other thermo-electrical involved effects, for example Thomson or Peltier effect-[VIC01], which can be considered as internal heat sources. To account these physical phenomena, Thomson or Peltier coefficient is necessary to be included in the model. However using code SysweldTM, other a) b) c) thermo-electric effects cannot be integrated. It is assumed that internal heat term ‘ Q ’ may be less significant and therefore neglected in the analysis, for instance. Details of finite element formulation for electro-thermal analysis is described and documented in the dissertation,-[THI92]. Generally, there are two possible methods for thermal computation; the specific heat, (‘ Cp ’), and the enthalpy model, (‘ H ’). However to effectively take into account the latent heat of phase transformations (especially, latent heat of transformation ‘ γ → α ’ and that of the fusion state from solid to liquid phase), the enthalpy model is more convenient than ‘ Cp ’ model. In addition, the integration of the metallurgy phase database associating with a phase transformation model to thermal computation, it is only possible with the use of enthalpy model-[FOR04], due to the relationship between thermal and metallurgical aspects. These relationships are : metallurgical phase transformations depend directly on the thermal history experiencing in the weld, thermal properties are phase-independent characteristics, and metallurgical transformations are accompanied by the latent heat effects, which modify the temperature distribution. Essentially, the enthalpy model is employed in our analysis basing on its unique model features mentioned above.