Checking whether an IC meets its specifications after the manufacturing process is an essential task to guarantee the device quality. However, this test process has a strong impact on the total cost of the product. This is particularly true for Analog and RF circuits that require complex and expensive test equipment with a long testing time to evaluate the circuit specifications. An interesting approach to reduce the testing costs is to adopt an indirect test strategy. The idea is to measure parameters that require only low-cost test resources and to correlate these measurements, called Indirect Measurements (IMs), with the device specifications. These correlations are often established using machine-learning algorithms.

Testing Integrated Circuits (ICs) is a crucial step in the production process as it ensures the quality of manufactured devices and verifies their reliability during their life-cycle. In the case of digital blocks, even though complexity has exploded over the decades, fault-oriented testing has allowed to limit the part of the testing costs of these blocks. On the other hand, for analog and RF blocks, even if they have less evolved in complexity than digital blocks, their testing costs have continued to increase. The main reason is that there is no recognized fault model for analog and RF blocks and therefore fault-oriented approaches are inadequate. In consequence, analog and RF circuits are tested with a specification-oriented approach, which relies on the measurement of the circuit performances and the verification of whether these performances comply with the datasheet. This approach ensures a satisfying test quality but the required measurements necessitate very expensive test equipment and long test time, which are responsible for the excessive testing costs [1]. Furthermore, recent design trends tend to experiment with heterogeneous systems and the notion of System-in-Package and 3D devices. Such advances raise new technical difficulties for the testing process in terms of access to the internal components in order to provide stimuli for specific inputs and the ability to read the device response on its outputs, which will of course result in additional test costs. Finally, when considering RF ICs, it would be complicated to rely entirely on wafer level specification-based testing for RF signals due to probing complexity [2] and limited resources [3].

Several approaches have been studied to avoid these direct performance measurements. All fault model-based solutions such as digital test techniques never achieved an acceptable level of test efficiency, even if recent solutions improve the effectiveness of these techniques. Built-in-Self-Test or DFT (Design For Testability) solutions often reduce the required external resources, but have a significant silicon impact, and above all, do not allow performance to be measured with the same accuracy as external measurement instruments. In this context, an interesting approach is to adopt an indirect test strategy based on machine-learning algorithms.

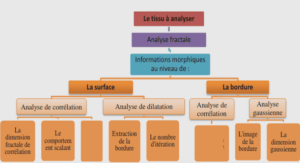

Endirect test for analog/RF integrated circuits was firstly introduced in [4] as alternate test. The main motivation behind such an approach is to alleviate the burden and relax the constraints on the industrial test equipment to process conventional performance specification measurements, which require additional dedicated and expensive equipment. The underlying concept of an indirect test strategy is that the process variations exhibited in the fabrication process that affect the device performances will also affect non-conventional low-cost indirect parameters easily measured by low-cost test equipment. Thus, it is possible to find and establish a correlation between the indirect parameter space and the performance specification space. As a result, the intention of establishing a correlation is to test only indirect parameters to verify the performance of the device under test.

However, the relation between these two sets of measurements is usually complex and not always easy to identify through analytical functions. One solution to overcome this problem is to utilize the computing powers of machine learning algorithms. The implementation of a machine learning algorithm can be under two distinctive forms in the context of an indirect test strategy; it could be either considered as a classification or a regression problem.

In the case of a classification-oriented indirect test, the idea is to establish a decision boundary that separates good from faulty circuits. This decision boundary is determined within the indirect measurement space. This approach has been previously presented in [5–7].

Of course, such an approach is only possible when the test limits are available to be able to establish a model that differentiates between these two classes. Indeed, implementing a classification-oriented indirect test is deemed as a fast strategy to classify new devices as either faulty or good circuits while only using rapidly executed low-cost indirect measurements. However, once the new device is classified, this approach does not offer any capabilities to diagnose the results of such a classification. Moreover, usually due to the life cycle of new devices, the specification test limits may change, which implies to re-define and re-establish a new decision boundary in the indirect measurement space to classify circuits as good or faulty.

The prediction-oriented indirect test is another implementation of an indirect test strategy, which has been previously explored in [8–10]. Instead of establishing a decision boundary, like in the case of a classification-oriented indirect test, in this approach the target is to establish a regression function that can predict the value of the device performance by building a regression function that maps the values of indirect measurements (IMi) into the performance measurements (Pj ) as expressed in Equation 1.1, thus dispensing the need of retaining the performance specification limits while establishing the indirect test strategy. fIM→P : [IM1, …,IMl ] → [P1, …, PN]. (1.1)

In fact, this strategy has several advantages over the previous strategy. The main advantage is that there is no need to re-establish the regression function that maps the indirect measurement space to the performance specification space each time the specification test limits vary during the life cycle of the device. Moreover, due to the produced performance estimation through the established regression function, it is plausible to diagnose, and interpret the indirect test strategy efficiency. Thus, in our work we have adopted the prediction-oriented test approach due to its advantages over classification-oriented strategy .

Introduction |