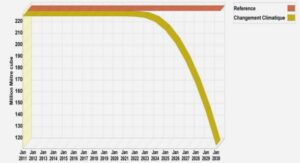

Forging processes are an essential step in the fabrication of a sound material. Void closure requires energy, in the case of hot forging, an increase in temperature coupled with energy transferred from exterior loadings in the form of plastic deformation, strain energy and void surface energy is produced. A major secondary effect is the activation of particle diffusion, necessary in the healing stages of void closure.

Principal hot forging techniques

A handful of hot forging techniques are used in today’s industrial climate. Open die forging or smith forging is paramount for workpiece sizes debuting as large ingots. Closed die forging is used for smaller parts and will therefore be omitted. The process of Upsetting and Cogging make up the prominent duo that lay the foundation a forging fabrication process. A brief description of these two hot forging operations follows.

Upsetting

Upsetting is a shape transformation technique for cast ingots in hot forging that consists in applying pressure to one side of a workpiece along its principal axis with flat a die. The aim of this process is a reduction in height which comes accompanied by an increase in width of the workpiece. Main process parameters include initial and final die heights. Heat transfer conditions and existing friction between die face and ingot can cause barreling if left unmonitored. Azushima et al. (2012) showed that the correct choice of lubricant can significantly reduce this phenomenon. High viscosity lubricants allowing for uniform displacements. Low viscosity fluids were shown to create a non-uniform distribution, increasing from the counterpoint to the periphery.

The compressive forces fathered from the upsetting process can be beneficial to the closure of internal voids or other defects engendered during casting. Lee et al. (2011) determined a non-unique response in void closure to upsetting. Various void behaviours were observed, depending on size and position in the large ingot. Hydrostatic stresses around the void were shown to switch from tensile to compressive to tensile conditions. Effective strain of over 0.6 was indicated to validate void closure conditions.

Cogging

Cogging or drawing out often follows the upsetting process in the forging of long, square, octagonal or circular sectioned, steel slabs. The operation takes place in steps, generally starting at one end of the workpiece and finishing at the other. The repetition of these steps is alternated with the rotation of the workpiece in order to reduce thickness and increase length.

Cho et al. (1998) investigated the cogging process design using Conventional flat (CV) and Free Mannesmann (FM) dies . FM dies proved more efficient, increasing hydrostatic stresses in the ingots center. Bite width was also evaluated, concluding that optimal parameters were obtained using 40 to 75% of the width of the die. Quicker forging can be accomplished using a smaller bite, increasing thickness reduction. Kakimoto et al. (2010) demonstrated that a reduction ratio of 75% was necessary in order to achieve soundness in the material matrix.

Table des matières

INTRODUCTION

CHAPTER 1 STATE OF THE ART

1.1 Introduction

1.2 A modern day scale

1.2.1 Macroscopics

1.2.2 Microanalytics

1.2.3 Mesoscopics

1.3 Void physics

1.3.1 Void origins

1.3.2 Void geometries

1.3.2.1 Simplified geometry (sphere, cylinder)

1.3.2.2 Equivalent ellipsoids

1.4 Influence of hot forging on void closure

1.4.1 Principal hot forging techniques

1.4.1.1 Upsetting

1.4.1.2 Cogging

1.4.2 Influential material and process parameters

1.4.3 Material behaviour during void closure

1.4.3.1 Local thermodynamic conditions in the workpiece

1.4.3.2 Effect on the local microstructure

1.4.3.3 Healing

1.5 Comparison of existing void closure models

1.5.1 STB model

1.5.2 Ragabs derived work of the Gurson-Tvergaard model

1.5.3 Budiansky’s model

1.5.4 Duva and Hutchinsons modified model

1.5.5 Zhang and Cui’s analytical model

1.5.6 Zhang’s semi-analytical model

1.5.7 Saby’s CICAPORO model

1.6 Characterisation techniques

1.6.1 Traditional void characterisation

1.6.2 Microtomography

1.6.2.1 3D microtomography

1.6.2.2 X-Ray microtomography

1.6.2.3 Synchrotron X-Ray microtomography

1.6.3 3D Reconstruction software

CHAPTER 2 PRELIMARY ANALYSIS OF THE OPEN DIE FORGING

PROCESS

2.1 Industrial partner and process selection

2.2 Forging sequence identification

2.2.1 Sequence 0: Initial forming

2.2.2 Sequence 1: Upsetting

2.2.3 Sequence 2: FM process

2.2.4 Sequence 3: Cogging

2.2.5 Sequence 4: Finishing

2.3 Process variability observation

2.4 Preliminary analysis

2.4.1 Data collection

2.4.2 Forging sequence characterisation

2.5 Preliminary conclusions

CHAPTER 3 DEVELOPMENT OF A FAST CONVERGING MATERIAL

SPECIFIC VOID CLOSURE MODEL DURING INGOT FORGING

3.1 Abstract

3.2 Introduction

3.3 Mechanical and material conditions

3.3.1 Ingot breakdown process

3.3.2 Stress and material behaviour assumptions

3.4 Determination of material dependant void closure constants

3.4.1 Development of material dependant model constant functions

3.5 Results and discussion

3.5.1 Evolution of void closure

Void closure model comparison

3.5.2 Influence of the triaxiality state

3.5.3 Influence of material parameters

3.5.4 Characteristics of the investigated alloy

3.5.5 Material sensitivity

3.6 Model validation for large size ingots based on experimental observations

3.6.1 FEM simulation setup

3.6.2 In ingot sensor positioning

3.6.3 Stress and strain evaluation

3.6.4 Simulation results

3.7 Conclusions

3.8 Acknowledgements

3.9 References

CHAPTER 4 ANALYSIS OF VOID CLOSURE DURING OPEN DIE FORGING

4.1 Abstract

4.2 Introduction

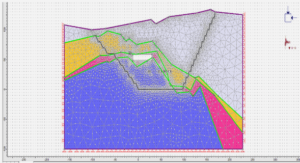

4.3 Finite element analysis

4.3.1 Finite element model

4.3.2 Rheological material model

4.3.3 Void closure model

4.3.4 Definition of virtual existing voids

4.4 Results and discussion

4.4.1 Void closure calculation method

4.4.2 FE results

4.4.3 Void closure analysis

4.5 Conclusion

4.6 Acknowledgements

4.7 References

CHAPTER 5 DEVELOPMENT OF A PREDICTION TOOL FOR SUCCESFUL

FORGING

5.1 Forge Calculus – prediction tool

5.1.1 In depth analysis of successful forgings

5.1.1.1 Sequence models

5.1.1.2 Sequence algorithms

5.1.1.3 Example of application

5.1.2 Individual results module

5.1.3 Statistical analysis module

5.2 Future development

CONCLUSION

|

Télécharger le document complet

Télécharger le document complet