Effet de lentilles gravitationnelles et polarisation du

fonddiffus cosmologique

CELLULOSE DISSOLUTION IN ALKALINE HYDROXIDE AQUEOUS SOLUTIONS

Cellulose is not a thermoplastic polymer. Thus, cellulose melting is not possible and dissolution is a necessary step to process cellulose. Because of intra- and intermolecular hydrogen bonds, the penetration of solvent is difficult and it has to be “strong” enough to break them. Different types of solvent can be used; they are largely described and classified by Klemm et al. [KLE1998]. The oldest process to dissolve cellulose is named “viscose process”: cellulose is chemically transformed before being dissolved, this is the xanthation step. But as this process is polluting, an alternative route is to dissolve cellulose in alkali hydroxide aqueous solutions. After describing the current industrial process (part I.2.1-), we will present the first studies on this new solvent of cellulose (part I.2.2.1). Our work was based on these data concerning experimental conditions: concentrations, temperature, additives. Several authors investigated cellulose/alkali hydroxide aqueous solutions (parts I.2.2.2 and I.2.2.3) in order to understand the dissolution mechanism. Some hypotheses are given concerning the mechanism at the level of fibres and microfibrils (part I.2.2.4), but there are practically no literature dealing with the mechanism at the molecular level. Concerning additives, it will be shown that the influence of the proportion between NaOH and urea or thiourea or zinc oxide was studied in details (part I.2.3-). However, the mechanism of the action of these additives still remains unclear, despites a rather large amount of publications. Pure cellulose (Pulp, cotton) Wetted cellulose (Pulp, cotton) Water Stocked at Troom Water content = 10% Water content = 100% Steam Explosion As-steam-treated cellulose (Pulp, cotton) Water content = 200% Water content = 10% Washed steam-treated cellulose (Pulp, cotton) P = 15 bars t = X sec. Stage 1 Stage 2 Stage 3 Stage 4 Washing

Xanthation in viscose process

The viscose process was discovered in 1892 by Cross, Bevan and Beadley and allowed spinning of viscose fibres. Still nowadays, the step of xanthation of this process is a method widely used in industry to dissolve cellulose. This process can be divided into three main chemical steps, which are identical in most of the industrial viscose processes (Fig.I.2-1). Fig.I.2-1: Scheme of viscose process (1) formation of alkali-cellulose, (2) xanthation (3) dissolution (1) Cellulose, prepared from either wood pulp or, less commonly, cotton linters, is treated with 17-20% sodium hydroxide (NaOH), at a temperature in the range of 18-25°C, to convert cellulose to alkali-cellulose. Cell-OH + NaOH → Cell-O- ,Na+ + H2O Cellulose fibres are swelling and become more accessible to other reactants. Then the alkali cellulose is aged under controlled conditions of time and temperature (between 18 and 30°C) in order to depolymerise the cellulose to the desired degree of polymerisation (DP). The molecular weight obtained determines the viscosity of viscose solution and cellulose concentration. (2) After this maturing step, carbon disulfide (CS2 ), in gas or liquid state, is added to the solution of alkali-cellulose to react with hydroxyl groups and generate the xanthation reaction: S Cell-O- ,Na+ + CS2 → Cell-O-C S- ,Na+ The resulting product is a substance called ‘cellulose xanthate’. (3) Then this alkaline cellulose xanthate is dissolved in dilute sodium hydroxide (~2.7 wt%) and forms a viscous solution called ‘viscose’. S S- ,Na+ Cell-O-C + NaOH + H2O → Cell-O-C OH + H2O S- ,Na+ S- ,Na+ (1) (2) (3) The large xanthate substituents on the cellulose force the chains apart, reducing the interchain hydrogen bonds and allowing water molecules to solvate and separate the chains. After obtaining viscose, industrial processes vary. The next steps can be: filtration and then spinning to obtain fibres or thin films, addition of reinforcing fibres and porophores then moulding to obtain sponges (see Chapter V), etc. The last step of processes is called coagulation: cellulose is precipitating in regeneration baths (water, acid or base). The final regenerated cellulose is obtained and CS2 and sulphured compounds formed during chemical reactions are going out. However, “viscose process” involves some pollution: in the atmosphere, because of CS2 and H2S, and in water, because of the reducing agents (containing sulphur compounds) which decrease the oxygen amount in water. Optimisation and improvement in the viscose process result in a total recycling of the pollutant compounds in the aqueous phase and in a decrease of pollutant compounds in the atmosphere. Nowadays the quantity of the latter is “only” 10% of CS2 used initially. Unfortunately, technologies for pollution treatment are very expensive. Thus for economical and for environmental reasons, it is very important to find new cellulose solvents. The purpose of research laboratories is to step away from the chemical modifications of cellulose by CS2 . NMMO, for example, is a good cellulose solvent, but these solutions are not very easy to prepare and to process. That is why it is interesting to look for alternative routes.

Action of alkaline hydroxide solutions on cellulose fibres

For a long time, it was known that strong alkaline aqueous solutions act on cellulose. Indeed, at the end of 19th century, Mercer [MER1903] discovered that cellulose fibres are swelling in aqueous solutions of sodium hydroxide and that was drastically changing the properties of the fibres. Several years later, in 1939, Sobue showed that cellulose can be dissolved in a narrow range of temperature and concentration of NaOH [SOB1939].

Introduction on mercerisation process and cellulose dissolution

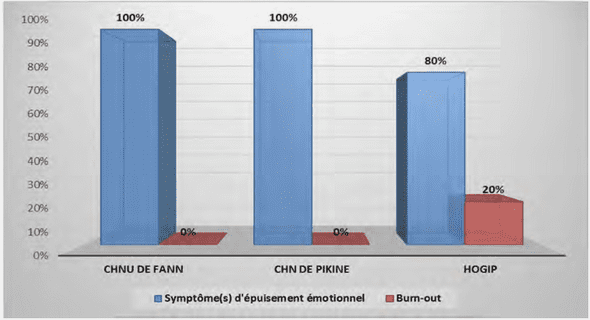

Mercerisation is a process, which John Mercer developed between 1844 and 1850. Cotton cloth is immersed in a strong caustic alkaline solution, and then washed, in order to improve the lustre and smoothness, for example. Mercerisation also increases the ability to absorb dye, improves the reactions with a variety of chemicals, the strength and elongation of fibres and the stability of form. This type of cotton is often compared to silk and is especially used to produce high-quality fabrics. But this process tended to shrink the cotton cloth. In 1889, Horace Lowe improved this technique by keeping the material under tension whilst being mercerised and he applied a more thorough washing process to remove the caustic soda. Thus the mercerisation became a viable textile process. During mercerisation, alkaline solution acts on cellulose chains by changing the fine structure, morphology and conformation of cotton. The native cellulose I crystalline form is transformed into cellulose II, resulting in a variation in fibre strength and lustre as well as adsorption properties. In addition, soda fills up almost entirely the central cavity (the lumen) of cotton fibres. So, the ribbon-like cotton fibres become perfectly cylindrical and loose their convolutions inducing a smoother and shinier texture [MAR1941]. In mercerising, a decrease in length of cotton hair is accompanied by an increase in diameter: cellulose fibres are swelling. According to Mercer [MER1903], mercerisation also occurs at low NaOH concentration (~9%NaOH) and the properties of cotton are improved. The lower the temperature, the more effectively the soda acts on the fibrous material. This reveals that the term of mercerisation was very wide and corresponded to all changes in cellulose fibres due to the action of alkaline hydroxide aqueous solutions. Several conditions of temperatures and NaOH concentrations are reported depending on material (cotton, ramie, flax, yarn or cloth…) and on process. The most often used conditions are 18-32% NaOH concentrations at 25-40°C. It is important to note that hardly few minutes (from 20s to 3min) are enough to obtain mercerisation of cellulose. Nowadays, the term of mercerisation essentially represents the action of concentrated alkali hydroxides on cellulose. The NaOH concentration and temperature conditions to swell cellulose fibres are relatively well determined and slightly change depending on cellulose origin. In 30’s, Davidson defined optimal conditions to dissolve modified cotton. As illustrated Fig.I.2-2, a decrease of temperature improves “hydrocellulose” dissolution in sodium hydroxide solutions [DAV1934] (“hydrocellulose” was obtained by cellulose hydrolysis with strong acids). Fig.I.2-2 [DAV1934]: Hydrocellulose solubility versus NaOH concentration and solution temperature The maximum solubility is 80% and it occurs at NaOH concentration of 10%, at –5°C. Moreover, the solubility increases when the chain length decreases. Consequently, authors concluded that unmodified cellulose cannot be dissolved because of the large length of the macromolecules. But, in 1939, Sobue et al [SOB1939] showed that it is possible to dissolve cellulose, from natural ramie fibres, in a narrow range of phase diagram: between NaOH concentrations of 7% and 10% at low temperature (-5°C/+1°C). In the 80’s-90’s, cellulose dissolution in 7-10%NaOH/water was largely studied. Kamide et al. [KAM1984] revealed that regenerated cellulose can be dissolved in NaOH/water and that the dissolution depends on the degree of breakdown in O3-H…O5’ intramolecular hydrogen bonds. They also showed that the cellulose solubility depends on the DP, the concentration and the crystallinity of cellulose samples. Some years later [KAM1990], the authors also compared the Xray diffraction peak intensities of cellulose I (∆I1 ) and Na-Cell I (∆I2 ) as a function of cellulose concentration in 9%NaOH/water. Fig.I.2-3 represents the results obtained. It appears that up to 9% of steam exploded cellulose (DP being ~340), there is no peak of cellulose I and no peak of Na-cell I. This means that 9%NaOH/water totally dissolves cellulose when its concentration is inferior to 9% and that the total dissolution of cellulose I (Ccell < 9%) in 9%NaOH aqueous solution gives a solution without conversion of cellulose I to Na-Cell I.

Résumé du Chapitre I |