Alloying elements are usually added to Al–Si cast alloys in order to improve microstructure features and thus improve mechanical properties. Nickel (Ni) and Zirconium (Zr) are used as alloying additions to increase high temperature strength in aluminum alloys due to the production of the L12-type precipitates Al3Zr or Al3Ni, which are more able to maintain overaging at higher temperatures than the precipitates existing in cast aluminum alloys such as Al2Cu and Mg2Si [60]. Manganese (Mn) is used to neutralize the effect of iron (Fe) and to modify the morphology and type of intermetallic phases formed. Scandium (Sc) in aluminum alloys acts as an effective grain refiner and increases the recrystallization temperature, the corrosion resistance, and weldability.

Zirconium (Zr)

Zirconium is added to aluminum to form fine precipitates of intermetallic particles that inhibit recrystallization [6]. For alloys with zirconium additions, a non recrystallized structure can be obtained after heat treatment which provides a high level of structural hardening for a wider range of semi-products than in the case of aluminum alloys containing manganese (Mn). These products include virtually all pressed and rolled plates, stampings, forgings, and some cold-deformed semi-products (sheets) obtained from Al-ZnMg and Al-Zn-Mg-Cu alloys, which require a lower temperature of heating for hardening (450°-470°C) than Al-Cu alloys.

Zirconium is usually present in aluminum alloys in an amount ranging from 0.1 to 0.25%. Segregations of the Al3Zr phase particles formed are finer than those of Mn aluminides (10-100 nm in size) [61]. However, the effect of precipitation hardening due to segregation of the Al3Zr phase is not high because of the low content of Zr in the alloys similar to the case of the Mn aluminides, although the effect of the finer zirconium aluminide segregates on the process of recrystallization in deformed semi-products and, accordingly, on their grain structure, is considerably stronger [5]. Additionally, it has been shown that Zr increases the resistance to overaging when it is added to binary Al-Sc alloys [62].

Nickel (Ni)

Cast Al-Si alloys usually contain alloying components such as magnesium, copper, nickel, etc. which are widely used in the automotive industry in piston applications [63,64]. These additions form intermetallic phases with complex morphologies and complex compositions. Nickel is added to Al-Cu and Al-Si alloys to improve hardness and strength at elevated temperatures and to reduce the coefficient of thermal expansion, as there is an increasing demand for Al-Si cast alloys with better performance concerning yield and tensile strength at elevated temperatures up to 250 °C [65]. In fact, the addition of alloying elements such as Cu and Ni is an effective and practical way to improve the mechanical properties, especially in relation to the performance of piston alloys which are subjected to high temperature service conditions [66].

The advantages of adding Ni and Zr to Al-Si alloys are that their precipitates (Al3Ni and Al3Zr) possess the following important characteristics:

• They are coherent;

• Possess low solubility;

• Directly affect the strength of the material because they act as hard pinning points which inhibit the movement of dislocations in the matrix.

Manganese (Mn)

Manganese is very soluble in aluminum; when the cast is chilled, most of the added manganese is substantially retained in solution. It increases the strength of the alloy either in solid solution or as a finely precipitated intermetallic phase by modifying the morphology of the intermetallic phases which are formed after heat treatment of the given alloy. As reported by Seifeddine et al. [67], it has no adverse effect on corrosion resistance. Manganese combines with Fe in the alloy forming the script-like α-iron phase which is more compact and less detrimental to the mechanical properties [68]. Hwang et al. [69] have reported that as the Mn content is increased up to 0.65 wt% corresponding to an Fe/Mn ratio of 1.2 in the Al-7wt.% Si-3.8 wt.% Cu-0.5 wt.% Fe alloy, the plate-like βAl5FeSi iron intermetallic phase is completely converted to the Chinese script αAl(Fe,Mn)Si iron phase, resulting in improved tensile properties. Excess amounts of Mn, however, deteriorate the mechanical properties by increasing the total amount of ironcontaining intermetallic phases formed.

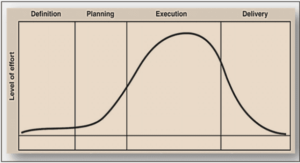

CHAPTER 1 DEFINING THE PROBLEM |