Heat Treatment Furnaces

Heat treatment furnace that provides the heat treatment medium inside, is one of the most vital equipment of heat treatment procedure which should be comprehensively studied to achieve optimum heat treatment of metals. There are several types of heat treatment furnaces that can be categorized based on their shape and movement of products within them (such as box furnaces, pit furnaces or tip-up furnaces) or the energy used in them (like electrical heated furnace or gas-fired heat treatment furnaces). Among different types of furnaces Gasfired heat treatment furnaces are extensively used for large-size high-strength steel products such as medium-carbon low-alloy steels for different critical applications in the energy and transportation industries. Natural gas usage in these furnaces provides the increased heat treatment rate and reliable burning (Totten, 2006). Final material properties are usually optimized by tempering parameters modification (such as temperature, time, etc.) in these heat treatment furnaces (Yan, Han, Li, Luo, & Gu, 2017). To analyze these furnaces, burners which provide the heat input as a result of combustion of the natural gas by oxygen should be studied comprehensively (Purushothaman, 2008).

Tempering of Large Size

Parts Large-size products, due to the significant temperature variation between their surface and center, contain different microstructures which in turn response differently to the tempering process (Talebi, Ghasemi-Nanesa, Jahazi, & Melkonyan, 2017). Besides, non-uniform temperature distribution in such parts within gas-fired furnaces may result in non-uniform properties in different locations of the final product or even cracking. Therefore, temperature distribution uniformity is of great importance for the quality of the final products (Gao et al., 2000; Gur & Pan, 2008). Further, due to their large sizes a lot of energy is used in these furnaces (Kang & Rong, 2006; B. Mayr, Prieler, Demuth, Moderer, & Hochenauer, 2017). Therefore, predicting, controlling and subsequently optimizing the temperature distribution of such parts is a necessary task to increase the product quality and reduce the production cost (Hao et al., 2008). However, an exact prediction of the furnace temperature distribution and, consequently, the temperature experienced by the product is difficult and the heating cycle schedules are mainly based on the available empirical correlations (Kang & Rong, 2006).

These correlations are usually valid for specific ranges of temperature and defined as a function of the furnace load and simple loading patterns of the parts inside the furnace (Canale et al., 2008; Korad, Ponboon, Chumchery, & Pearce, 2013). Hence, large deviations in the case of large-size products multiple loading patterns are observed (Cheng, Brakman, Korevaar, & Mittemeijer, 1988; Gao et al., 2000; Primig & Leitner, 2011). On the other hand, most of the metallurgical studies assume a constant heating rate in different locations of the part, which is far from the reality and proves the need for accurate determination and prediction of temperature evolution inside the gas-fired heat treatment furnaces and subsequent analyses based on these temperature profiles. An accurate temperature prediction of parts necessitates a quantitative analysis of thermal interactions and their subsequent roles on the transient heating of large size parts inside gasfired heat treatment furnaces as detailed in the following sections.

Thermal Interactions inside a Gas-Fired Furnace Heat is a form of energy that exchanges between several mediums due to temperature differences. This transfer of energy which always takes place from the higher temperature field to the lower one, according to the first law of thermodynamics, is the basis of the heat transfer (Incropera, Lavine, Bergman, & DeWitt, 2007). Gas-fired heat treatment furnaces transfer heat to the different location of parts through the three modes of heat transfer: radiation, convection and conduction. As it can be seen in the schematic view of interactions inside a heat treating furnace (Fig. 1.3) the three modes of heat transfer are playing their role in a conjugate situation. Therefore, any analytical, experimental or numerical study should consider the conjugate heat transfer to analyze the heat transfer rates. It should be noted that these heat transfer modes take place in combination with the two main fluid flow related interactions (combustion and turbulence) which will be discussed in the following sections.

Turbulence Almost all fluid flows which we encounter in the world are turbulent. Turbulent flows can be usually observed in numerous natural and industrial cases like impingement flows or burner combustions (Fig. 1.5). The boundary layers and the wakes around and after bluff bodies such as cars, airplanes, buildings and large-size steel parts in the heat treatment furnaces are turbulent. In the turbulent flow field of study, the parameters such as velocity are decomposed in two parts of a time-averaged, 𝑈ഥ, which is independent of time (when the average flow is steady), and a fluctuating part, 𝑢́ , which means that 𝑢 = 𝑈ഥ + 𝑢́ . There is no exact definition of turbulent flow, but it has a number of characteristic features such as irregularity, continuity, diffusivity, large Reynolds numbers, a three-dimensional nature (Cant, 2001; Tennekes, Lumley, & Lumley, 1972). These characteristics can be found in several gas-fired heat treatment furnaces which are designed to have a self-induced turbulence. The high momentum of combustion products, with a large Re number, are in continuum interactions and provide 3D circulation inside the furnace.

Analytical and Semi-Analytical

Studies Thermal interactions inside the gas-fired heat treatment furnaces importing strong non-linear thermal boundary conditions to the loads make the thermal analysis of heat treatment process very difficult. In the literature Chapman et al. (Chapman, Ramadhyani, & Viskanta, 1990) in a semi-analytical study, assessed various material properties on the efficiency of heat treating process in a direct fired batch reheating furnace. Gao et al. (Gao et al., 2000) using heat conduction rule in solids, developed an analytical, practical virtual sphere method to estimate the equilibrium time and heating/cooling rate in heat treatment furnaces. Their results proved that the convection heat transfer rate could significantly differ from the empirically calculated h values for specific furnaces. Singh et al. (Singh, Talukdar, & Coelho, 2015) in their semi-analytical studies developed a heat-flow model to estimate temperature evolution of products in different heat treatment processes such as heating in electrically furnaces, air and water quenching. However, analytical analyses are generally limited to linear problems and they become very complicated in gas-fired furnaces where strong non-linear transient condition and interactions are present.

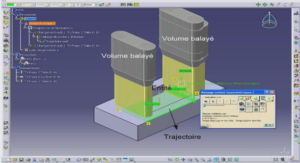

CFD Studies In this context, major advances have been made in development of high performance computational facilities allowing for the simulation of large size furnaces. Studies such as those of Jaklic et al. (Jaklič, Glogovac, Kolenko, Zupančič, & Težak, 2002) and Tagliafico et al. (Tagliafico & Senarega, 2004) using finite-difference and finite element based methods added more details to the analysis of load-furnace heating characteristics. Recently, computational fluid dynamics (CFD) offering simultaneous analysis of turbulent fluid flow, combustion and conjugate heat transfer has been used to simulate thermal flow field in various metallurgical processes (Szajnar, Bartocha, Stawarz, Wróbel, & Sebzda, 2010; S. F. Zhang et al., 2009; Zhou, Yang, Reuter, & Boin, 2007) (See Fig. 1.7). Yang et al. (Yang et al., 2006) using the ANSYS Fluent software (ANSYS, 2016) performed CFD evaluation of various metallurgical applications including: melting of aluminum scrap in a rotary furnace, molten hot metal flow in a coke-bed blast furnace, electric arc furnace and gas-fired heat treating furnaces. They used 𝑘 − ɛ turbulence model alongside with the EDM combustion model. Several radiation models including, P-1, DTRM and Monte Carlo model (MCM) have been evaluated in different industrial furnaces. The capability of these approaches to predict the thermal interactions inside the furnace has been confirmed by the authors. They also presented several data, including temperature evolution, melting curves and gas consumption profiles proving the CFD applicability in predicting flow, temperature, mass fraction and reaction distribution. Wang et al. (J. Wang et al., 2008) predicted the temperature field of a gas quenching furnace using CFD simulation and Cosentino et al. (Cosentino, Warnken, Gebelin, & Reed, 2013) investigated the non-uniform quenching effect on the product properties.

INTRODUCTION |