Fluctuations of Pavement Temperature

The variation of temperature in asphalt pavement can lead to the fact that significant daily fluctuations in temperature from 0 𝐶° to over 60 𝐶° increase the rigidity of the bituminous mixture, which makes the pavement surface vulnerable to thermal cracking. In such a situation, only lowering the viscosity of the asphalt binder or reducing the hardening rate of the bitumen binder will be beneficial in reducing the thermal cracking potential (Mashaan et al., 2014). It is generally accepted that bituminous hardening is a good relative measure of the durability of asphalt. Many researchers reported that a low quality of bitumen binder is due to premature aging problems in hot and dry regions in different parts of the world (Lei, 2011). Temperature is an important factor affecting the performance of asphalt pavement, the change in the quarterly and daily temperature can lead to certain types of asphalt pavement distresses, such as permanent deformation and bleeding are usually associated with high temperature; thermal cracking is associated with low temperature environments (Dawson 2014; Dawson et al., 2012). In 1987, SHRP Launched a long-term road traffic monitoring program (LTPP) to facilitate the pavement performance analysis, leading to enhanced engineering criteria for the mix design, execution of the asphalt pavement, and management of road networks. In 1991, the LTPP established the Seasonal Monitoring Program (SMP) to evaluate and assess the effects of solar radiation, humidity, and temperature changes on the asphalt mixture properties. The pavement temperature prediction and measurement were developed using SHRP test and SMP data to help in the selection of the proper PG asphalt performance grade related to the climate condition (Sreedhar, & Biligiri, 2016).

Energy Equilibrium in Asphalt Pavement

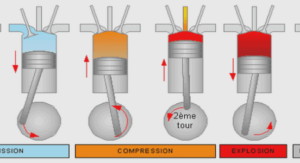

The main types of heat transfer are the thermal and longwave radiation between the road surface and the sky, phenomenon of solar radiation, and convection consequent to heat exchange between the fluid and road surface that is in contact with the surface and conductivity inside the road pavement layers, as shown in Figure 2. Solar radiation leads to heat gain on the road surface due to the absorption of solar energy. Convection heat flow concerns the fluid velocity and direction of the fluid, it relies on the speed and direction of air moving on the surface of the pavement (Dawson et al., 2012). The coefficient of heat transfer increases due to high air speed and compatible wind directions; the convective heat flow also increases (Athienitis, 2013). Thus, at relatively high air speeds, convective surface cooling occurs when the temperature of the wind is lower than the temperature of the road surface.

Variation of Solar Radiation Libya for example is located in a harsh HA climate, where about 88% of the cities are considered desert. The desert climate in Libya is almost clear and sunny; So, there is a high chance of solar radiation in the region (Mahgoub, & Mohamed, 2016). Some of the solar radiation is absorbed by various compounds in the atmosphere, some is scattered, some is reflected in space, and the rest arrives to the Earth as direct solar radiation (Lee et al., 2014). The intensity of incoming solar energy varies widely during the day, and also during the year. For example, at the location of the city of Gate, the radiation ranges from zero tonight to a maximum of about 1300 watts per square metre of W / m2 in the mid-day (Uzelac et al., 2014). Normally, the solar radiation transfers through empty space. The variations of solar energy between day and night and throughout the year, causes the rise and fall of daytime temperature; moreover the huge absorption coefficient of the black body (Asphalt pavement) to solar radiation, leads to the upper layers of the asphalt pavement being rapidly affected, in contrast to the lower layers (Qin, & Hiller, 2014). Therefore, before introducing the influence of solar radiation on the layers, this work introduces the prediction model of the asphalt pavement temperature in different depths as a part of this thesis.

Changing the Properties of Bitumen Due to Hardening The aging of the asphalt binder is an operation of the changing in properties of bitumen due to hardening and oxidation, which change the structure and composition of the asphalt bitumen (Xu, & Wang, 2017). The temperature, presence of oxygen, and arid climate lead to a quick reduction of the volatile compounds in the bitumen.19 The change of the bitumen properties leads to a decrease in penetration and increases hardening of the bitumen (Soenen, Lu, & Laukkanen, 2016). Short-term aging is affected by the source of bitumen, time of the mixing, temperature, and chemical composition. Long-term aging is mainly due to hardening of bitumen and climate conditions (Abdelaziz, 2018). Long-term aging occurs commonly in the bitumen layer for the presence of oxygen, and the pavement temperature changes (Kumbargeri, & Biligiri, 2016). Aging in operation, which occurs when the oxygen and moisture react with the asphalt binder (bitumen) in the presence of air (Wang et al., 2019). Aging of bitumen is one of the main elements affecting the pavement performance when the bitumen is exposed to a various range of temperatures during mixing, lying, and storage. Superpave versus Marshall mix design method The Marshall mix design method continues to be commonly used in developing countries, such as Libya. This method is easy to use and low-priced and it depends on a single piece of equipment to design and control the asphalt-aggregate formulation.

However, many engineers believe that the impact compaction obtained with the Marshall method does not thoroughly simulate the compaction at the field. Actually, the Marshall mix design method principles allow the designer to choose an OBC in a specific asphalt-aggregate mix design formulation where the desired properties of stability and flow are met. The construction of asphalt pavement using the Marshall method requires in most cases, a compaction of 95% or greater of the maximum lab value. It is possible to achieve a maximum density greater than 100% due to the limitations on the control sample in the lab and the unlimited compactive effort available in the field. If a pavement material is compacted over 100%, this means that the percentage of air voids is null and air is completely removed from the asphalt mixture. Consequently, there has been a growing feeling among asphalt experts that the Marshall method is no longer valid for modern asphalt mix design. The objective of the Superpave mix design method is optimize asphalt mixture resistance to pavement distresses. The Superpave mix design method introduces new equipment and notions, such as the Superpave Gyratory Compactor (SGC) and asphalt binder (PG) to take into account projected traffic and climate conditions, as well as mix design changes. The SGC can provide information about the compatibility of the particular mixture by capturing data during compaction, and the PG must meet performance criteria respectively at the hottest and the coldest annual pavement temperatures. The differences between the Superpave and the Marshall mix design methods are mainly in the material selection procedure, the compaction method, specimen dimensions, void analysis approach and specifications. Besides, adoption of the Superpave mix design method provides advantages of extended paving temperature, reduction in fumes, and improved environmental compatibility.

INTRODUCTION |