Technological workflow from data acquisition to surgery

Reconstruction

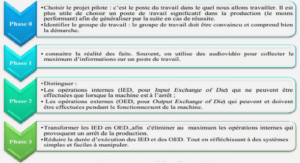

A CT scan with a 1 mm slice thickness is performed at the veterinary clinic on both front limbs of the ailing dog. The paws are positioned with extension of the antebrachiocarpal joint with a normal standing angle determined for each individual dog. The veterinary surgeon identifies the tumor on the CT scan and marks the optimal cutting distance from the antebrachiocarpal joint, taking into consideration a 5 cm margin of safety beyond the border of the tumor. The DICOM images are transferred through cloud storage to the engineering team. The images are processed with Mimics Research19 (Materialise, Leuven, Belgium), and the reconstructed bone structures are used for the implant and cutting guide designs . A segmentation procedure is finally carried out to separate the radius, ulna and carpal/metacarpal bones on the affected limb and the healthy radius, on the contralateral limb . The bone models are smoothed and exported in STL format into a CAD environment .

Computer-Aided Design

The contralateral (healthy) radius which is of similar size and proportion is mirrored and superposed on the affected radius . Next, the osteotomy plane is created at the prescribed distance perpendicular to the long axis of the bone . The affected part of the radius is virtually removed and replaced by its healthy counterpart . A contoured plate, featuring conical self-locking threaded holes, is created to accept commercially-offered screws . Afterward, the contoured plate, the healthy radius section and an intramedullary stem, corresponding to 70% of the intramedullary canal diameter are joined via additive Boolean operations. Then, subtractive Boolean operations are carried out with the objective of ensuring perfect surface contact between the endoprosthesis and the bones: the carpal/metacarpal bones and the salvaged part of the affected radius are removed from the plate. Finally, the implant thickness is verified and thin areas are reinforced .

A parametric cutting guide template is then placed on the radius and adjusted to comply with the bone geometry. It features a cutting slot that coincides with the previously created osteotomy plane, ensuring correct alignment between the cut and the endoprosthesis ,To create matching surfaces, Boolean operations of removal are performed on the guide using the ulna and radius solid models.

Manufacturing of endoprosthesis and cutting guide

The endoprosthesis is manufactured using a Ti-6Al-4V alloy powder (Ti64) and a laser powder bed fusion (LPBF) EOSINT M280 400W Ytterbium fiber laser system (EOS GmbH, Munich, Germany) . This alloy has the advantage of being corrosion- and mechanicallyresistant, low-stiffness and lightweight material (yield stress of 1000 MPa, Young’s modulus of 110 GPa, and density of 4.41 g/cm³ ). Multiple studies in recent years have discussed the biocompatibility of additively-manufactured Ti64 medical parts, concluding that this material is suitable for use in load-bearing implants (Haslauer et al., 2010; Murr et al., 2009; Sing et al., 2016; Vandenbroucke et Kruth, 2007; Wang et al., 2016; Yan et al., 2015).

Given that the LPBF process fuses powder locally, significant thermal stresses are induced in the part due to rapid temperature changes and significant temperature gradients. To prevent resulting thermal distortions and stabilize the parts during manufacturing, supports that bind the parts to the manufacturing plate are generated beforehand, using Magics 17 software (Materialise, Leuven, Belgium). A combination of fully dense and hatch supports is used to ensure firm attachment of the part to the build plate.

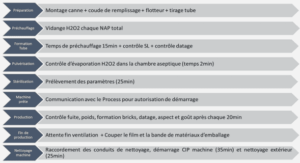

Once the supports are generated, model slicing and laser path programming are performed using the PSW 3.6 software (EOS GmbH, Munich, Germany) . Fabrication parameters were set to the ‘EOS Ti64 Performance Parameters Set’, which uses 30 micronthick layers. After manufacturing, the solid parts and the build plate are cleaned of loose powder . Residual stresses are released by performing an EOS recommended 4- hour heat treatment at 800°C in an inert gas (argon) atmosphere . During heat treatment, the build plate is placed in a protective gas box of an N41/H furnace (Nabertherm GmbH, Lilienthal, Germany) and ultra-high purity argon (5.0) is pumped into the box at the following rates: 15 L/min during the treatment and 25 L/min, during preflushing and cooling.

INTRODUCTION |